Why do scrap grades control scrap flows, customers and discounts?

Clean, well-sorted scrap with known composition and very low contaminants can substitute for primary metal in many applications and earns premiums. Specs of the usable scrap follow the finished product:

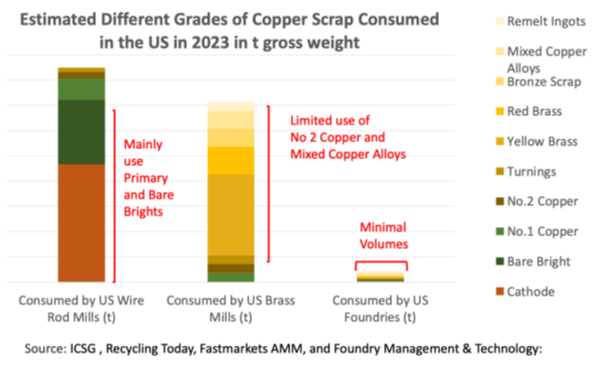

- Copper power cable and rod producers need 99.99% pure copper. Rod mills can only use high scrap grades such as bare brights and No. 1 copper scrap; lower grades require refining, adding cost.

- Aluminium can-stock and auto body sheet producers require tight, single-alloy chemistry scrap (e.g., 3xxx for can stock, 6xxx for auto sheet) and very low tramp content (Fe, Si, Cu, Zn, Mg).

- Mills prefer closed-loop scrap (UBCs, auto body sheet loops etc.) and manufacturing scrap (rejects, returns, chips and turnings) as the chemistry is known and repeatability and yield are consistent.

- Brass mills also require tight alloy chemistry scrap defined by their final products.

- Foundries with more forgiving metallurgy (gray iron, secondary Al die-cast) often accept broader residual ranges and mixed grades.

Scrap flows follow grade-specific supply and demand balances, which define scrap grade-specific discounts. Further processing may upgrade lower-quality material to higher quality through sorting or refining. Freight costs, and import/export rules, also steer flows.

As a rule of thumb, high-grade, high-value scrap is usually used locally; lower grades are exported to regions with lower cost labour/energy for upgrading.